Jones Hovercraft Snowboard 2023

Jones Hovercraft Snowboard 2023

Model Info

Out of Stock

But fear not - there is plenty to explore...

Shop all Jones Shop sale JonesMEMBERSHIP

Earn up to 10% back in rewards. Learn more. Join Free.

LOWEST PRICE GUARANTEE

Find a better price? We’ll beat it by 5%. See our Price Match Policy.

Product Info

The true float tank! The Jones Hovercraft Snowboard will levitate you through any snow. Really. The way its nose refuses to dip is remarkable, like a wine cork on JELL-O. Made for resort swooping and deep snow floofing, the Hovercraft's always ready to change directions no matter how deep the snow is. Whether it's afternoon leftover slaloms on the edges of a chopped up run, heli runs down untouched bowls, or somewhere in between: if there's any new snow at all, it may as well be bottomless on this thing. You know how your local resort pumps up their new snow totals? It's possible their reporters are riding Hovercrafts, totally oblivious to reality.

Product Details

Rocker Type

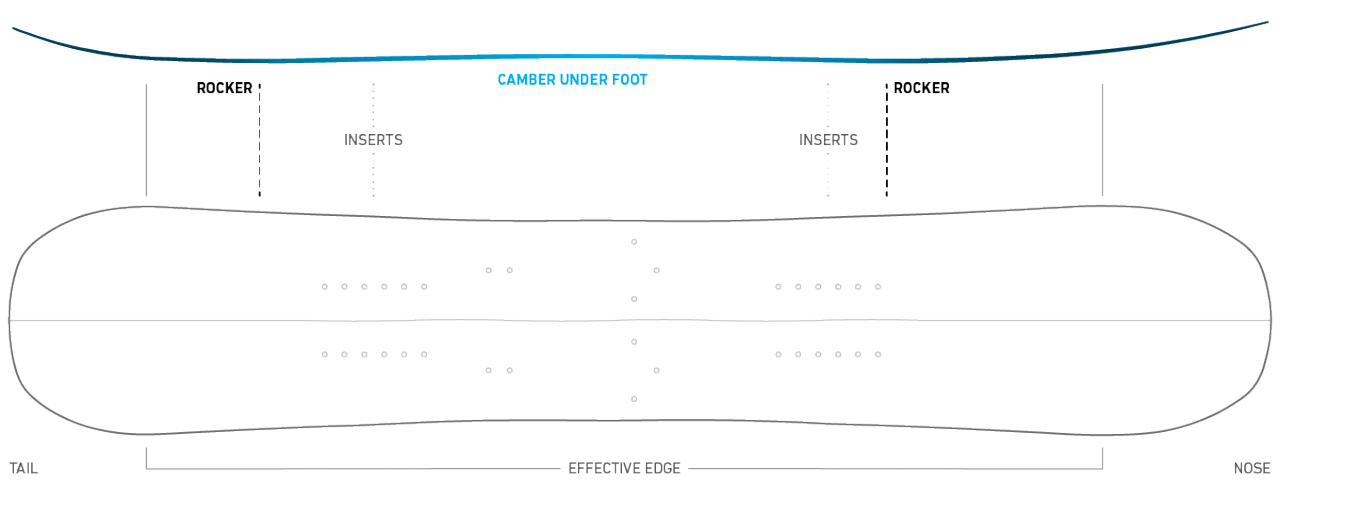

Directional Rocker – A hybrid rocker/camber flex pattern defined by more tip rocker then tail rocker and camber between the bindings. The rockered tip floats the board’s nose and improves maneuverability while the camber underfoot provides edge hold and response. A slightly rockered tail maintains the power and stability of a traditional board but helps keep the tail catch-free initiating turns and landing switch.

Flex

Flex Rating – 7 (1 Soft - 10 Stiff)

Forever Flex – All Jones boards are broken in using specialized machinery that mimics extreme riding use to help stabilize the flex and rocker profile of a board for it's lifetime.

Directional Flex Pattern

Shape

3D Contour Base 3.0 – Freeride focused 3D Contour Base featuring a 7mm of spoon bevel in the nose and 0 - 7mm of spoon bevel in the tail. Spoon bevel starts at the rocker point.

Blunt Nose – "How a board glides in powder, crust, corn or any snow more than an inch deep is dictated by it's front contact point and just past it. Next time you are in soft snow watch how much snow comes over the corner of the nose near the contact point. The billowing snow coming out from behind the tip means you are plowing through it which is obviously slowing you down. By adding a blunt nose you get the float benefits of a much longer nose without the 'snow plow' rounded tip and it's extra swing weight." - Jeremy Jones

Progressive Sidecut – At the far ends of the sidecut, the radius is incrementally increased as the edge reaches the contact point. Gradually increasing the sidecut radius towards the contact point delivers smoother turn initiation and exit as the edge tracks in and out of the snow with a less abrupt transition.

Core

FSC® Classic Core – Full wood premium poplar core that offers fun pop, even flex and solid durability.

V-Core – Slightly softer in the very center of the board for improved maneuverability and stiffer from the inserts through the tip and tail for stability and pop.

Laminates

Biax Fiberglass – A dual-direction, dual-layer, stitched fiberglass laminate that provides a fun, forgiving and snappy ride.

Sidewalls

Recycled ABS – ABS plastic is one of the necessary evils of snowboard production. Jones improves the sustainability of their snowboards by using only recycled plastic.

Base

Sintered 8000 Base – New super durable material made from Ultra High Molecular Weight polyethylene and carbon.

Edges

Oversized Recycled Edges – All Jones boards are made with oversized recycled steel edges for added durability and improved production sustainability.

Traction Tech 1.0 – Like a serrated knife slicing into the snow, Traction Tech improves your edge grip by adding multiple contact points along the running length of your board.

Topsheet

FSC® Engineered Veneer – Composite wood veneer topsheets made from 100% FSC certified wood. Wood veneer topsheets dampen ride and absorb board chatter.

Graphics

Ink-free Laser Engraved Graphics

Additional Features

Factory Tuned – All Jones snowboards are factory de-tuned at the tip and tail so you can go right from the shop to the mountain.

Wend Natural Wax – Jones boards are ready to shred straight out of the shop and are factory waxed with WEND natural wax.

Bio Resin – All Jones boards are now built with bio-based, renewable epoxy instead of petroleum based epoxy. The raw materials used to make Super Sap Bio-Resin are co-products or waste products of other plant-based industrial processes. Producing Super Sap requires 33% less greenhouse gas emissions than conventional epoxy.

Binding Compatibility

2 x 4 Insert Pattern

Specs

-

Terrain:

Freeride, Powder

More

Terrain

Freeride Freeride snowboards are designed for the rider that spends most of the day off groomed runs and in backcountry terrain. They typically have a stiffer flex and are ridden in longer sizes than freestyle snowboards. Freeride snowboards often feature a directional shape that is designed to perform optimally in one direction. Powder Powder snowboards love powder. Often associated with freeride snowboards, powder boards sometimes feature a wider nose and a tapered narrower tail. The binding inserts, which determine the rider's stance, are often set back on a powder snowboard to help the rider float the tip of the board through the deep stuff. Powder snowboards sometimes also feature rocker, a design element where the tip (and tail) rise starts farther back on the board, which also helps the rider maintain tip float through the pow.

-

Ability Level:

Advanced-Expert

More

Ability Level

Advanced-Expert Whether you charge the steepest lines, hit the biggest jumps in the park or carve with race-like precision, advanced to expert level skis, snowboards, boots and bindings are for the more aggressive rider. In skis and snowboards, you'll often find layers of metal, carbon or other stringers for rigidity and power, while advanced to expert level boots and bindings are usually on the stiffer side of the spectrum for rebound and precision steering.

-

Rocker Type:

Rocker/Camber/Rocker

More

Rocker Type

Rocker/Camber/Rocker Rocker/Camber/Rocker shapes seek to give you both hard-carving edgehold on firm snow from camber underfoot with enhanced turnability and float in powder from the rockered tip and tail. This profile is increasingly popular for freeride boards designed primarily for soft snow.

- Shape: Directional

- Binding Mount Pattern: 2x4

- Core/Laminates: Wood

- Snowboard Awards: The Good Ride Favorites

-

Warranty:

3 Years

More

Warranty

3 Years Visit https://www.evo.com/warranty-policy for more info.

| Size (cm) | 148 | 152 | 156 | 160 | 164 |

|---|---|---|---|---|---|

| Effective Edge (mm) | 1156 | 1191 | 1225 | 1257 | 1289 |

| Tip Width (mm) | 296 | 298 | 305 | 310 | 314 |

| Waist Width (mm) | 249 | 254 | 260 | 264 | 268 |

| Tail Width (mm) | 284 | 287 | 293 | 299 | 303 |

| Sidecut Radius (m) | 7.9 | 8.9 | 9.3 | 9.5 | 10.0 |

| Stance Setback (mm) | 20 | 20 | 20 | 20 | 20 |

| Rider Weight (lbs) | 90 - 140 | 110 - 160 | 130 - 180 | 160 - 210 | 170 - 220 |

| Width | Regular | Regular | Regular | Wide | Wide |